Blog

Damascus Folded Steel: An Ancient Art with Modern Appeal

Damascus folded steel which is known for its beautiful patterns and unique strength has attracted sword smiths, craftsmen, and collectors alike from ancient times. This method of folding and forging steel originated in ancient times and is an art and metalworking which is meant to produce a functional blade and also one which is attractive. In this paper, we will explore the history of damask, the damask producing processes, and the key steps involved in forging damascus folded steel.

What is Damascus Folded Steel?

The term ‘Damascus folded steel’ represents one particular type of steel that is characterized by a wavy surface pattern resembling the surface of a liquid. Most engineers also comprehend how to make this type of steel: separating two or more types into sheets, folding them several times, and baking them. What you get is a blade that is hard, has patterns, and is also relatively flexible.

Why Is It Called Damascus Steel?

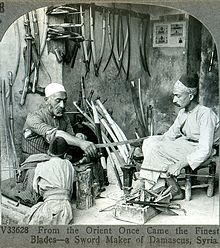

The name “Damascus” originates from the ancient city of Damascus, the capital of modern-day Syria, where the steel was believed to have been produced or traded. However, it is also possible that the name refers to the patterned appearance, which resembles Damascus textile patterns. Whatever the origin, the unique combination of beauty and performance in Damascus steel has made it highly sought after.

The History Behind Damascus Folded Steel

image credit by wiki

The origins of Damascus steel date back to at least 300 AD, and possibly even earlier. The steel was originally used for making swords and knives because of its combination of durability and sharpness. Warriors from ancient Persia, India, and the Middle East prized Damascus swords for their ability to hold a sharp edge and withstand battle without breaking.

Evolution Over the Centuries

Though the method of producing Damascus steel was lost around the 1700s, modern metallurgists and blacksmiths have revived the practice. Today, modern Damascus folded steel is crafted with more advanced techniques but retains the same principles that were used thousands of years ago.

The Forging Process of Damascus Folded Steel

Crafting Damascus folded steel is a complex process that requires precision and skill. The forging technique involves layering and folding metal to achieve both strength and the characteristic wave-like patterns.

1. Choosing the Steel Types

The first step in forging Damascus steel is selecting two or more types of steel. Typically, high-carbon steel is used in combination with a softer, more flexible type of steel. The contrasting properties of these metals are what make Damascus steel strong yet flexible.

2. Stacking and Welding the Layers

Once the steel types are chosen, the metals are stacked on top of each other in alternating layers. The stack is then welded together under high heat. This initial fusion is crucial to ensure the metals bond properly.

3. Folding the Steel

The process of folding is where the magic happens. After the initial weld, the steel is hammered and folded onto itself multiple times. Each fold doubles the number of layers in the steel. For example, folding the steel 10 times can result in over 1,000 layers. The more folds, the more intricate the final pattern.

4. Hammering and Forging

The folded steel is then repeatedly heated, hammered, and forged. This step ensures that the layers bond together seamlessly and the steel is shaped into the desired form. The repeated heating and hammering help to distribute the carbon content more evenly across the blade, contributing to its durability.

5. Pattern Development

The famous Damascus patterns start to emerge during the forging process. The layers of steel create contrasting light and dark streaks that flow across the surface of the blade. These patterns can be manipulated by the smith through techniques like twisting or etching to create various designs.

6. Heat Treatment and Quenching

Once the cutting surface has taken its shape, it is subjected to the processes of heat treating to harden the edge of the tool. The cutting blade is brought to an appropriate temperature range and then dunked into oil or water in order to maintain its hardness. This step also helps enhance the sharping retention ability of the blade.

Why Damascus Folded Steel Is So Revered

What sets apart the Damascus folded steel is the convergence of form, functionality, and aesthetic worth. Swords, knives, and other blades made from this material not only serve their functions but also are works of art. It is not so strange that many collectors and lovers of knives like to acquire Damascus’ blades, since history comes into play with its creation and no blade is identical to the other one because of the pattern.

Conclusion: A Timeless Craft

Damascus folded steel is perhaps the most historically popular type of metalwork. From ancient warriors to contemporary artisans, the technique has passed through the ages and has not lost its magnificence. It’s practical for a collector or a smith, who is also a lover of the beautifully made items – the process of forging Damascus folded steel is a culmination of art and its usefulness focally at the same time.