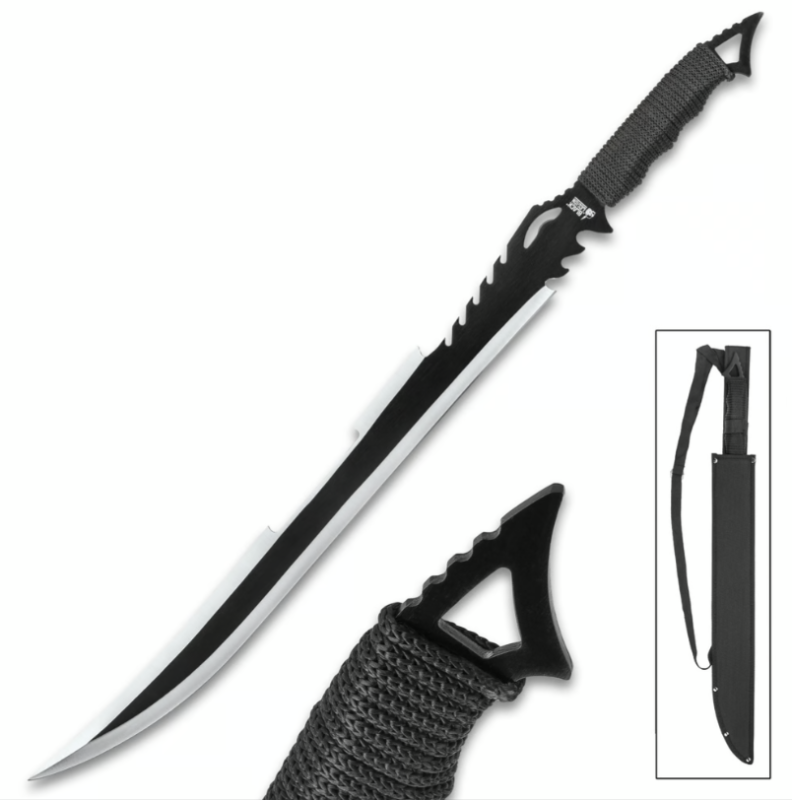

Shikoto Rurousha Handmade Katana

$545.92 Original price was: $545.92.$272.96Current price is: $272.96.

- Bound in rustic genuine leather, unbound by convention – distinctive katana bucks trends, boasts a style all its own

- Full tang 30″ Damascus steel blade accented with twin fullers, engraved kanji; expertly hand forged by seasoned swordsmiths using proven, centuries-old techniques

- Blade boasts thousands of distinct layers of high carbon steel – a sea of contrasting lines, waves, ripples, swirls and other spellbinding patterning

- Tsuka wrapped in genuine leather thongs for unique visual appeal, comfortable no-slip grip; flawlessly cast tsuba with clean, contemporary design

- Hand lacquered wooden saya protects blade; handsome mottled color scheme, genuine leather wrapping

- Overall length: 41 1/4″ – the quintessential full-sized Japanese samurai sword; powerful yet easy to wield

Description of Shikoto Rurousha Handmade Katana:

Bound in cowhide however unbound by show, the Rurousha is no conventional katana

Shikoto’s “Rurousha” Katana might be stunningly bound in certified cowhide groups, however it will not be limited by customary ideas of “conventional” sword plan. Furthermore, with regards to shear strength and crude cutting power, the Rurousha essentially exceeds all rational limitations. To be sure, the Rurousha is unique in style, designing, arrangements and that’s only the tip of the iceberg – from its vigorous, stunningly gorgeous. Damascus steel sharp edge to its provincial, cowhide driven attire and then some.

Swordcraft masterfulness just a carefully prepared hand could deliver

Shikoto fostered the Rurousha in view of the serious fighter. Ace smiths meticulously hand manufacture each sharp edge, and prepared sword craftsmans cautiously handcraft each tsuka and saya. From overwhelmingly pounding the liquid cutting edge steel to warily folding the cowhide straps over the tuska and saya, each move toward the Rurousha’s development gets extreme attention to detail and exact scrupulousness. A portion of the world’s – and history’s – most loved, depend methods are utilize, and each material meets or surpasses severe quality principles. A quintessential model is the Rurousha’s attractive Damascus steel tanto cutting edge, which overflows with power and visual magnificence – a fabulous marvel by its own doing, with its differentiating lines, waves, twirls and other hypnotizing designs.

Old hand producing procedure yields unmistakably current katana

Basically, an expert Shikoto Rurousha Handmade Katana from the old sword making town of Longquan fires a heap of steel strips – each an alternate combination – in a white-hot fashion until the metal sparkles cherry red. He then, at that point, eliminates the stack and mallets it until it’s around half as thick as the first. Then, at that point, he overlays the metal onto itself longwise and pounds every half together. The cycle is fastidiously rehash – many times now and again – until the ideal layering impact is accomplish, so, all in all a last extinguishing fortifies the subsequent sharp edge clear and a corrosive scratching features striking differentiations in the layers.

2 reviews for Shikoto Rurousha Handmade Katana

Shipping & Delivery (USA, Canada & Australia)

For US orders, handling time is 1–3 business days, and shipping usually takes 8–10 business days (excluding weekends and public holidays). We also ship to Canada and Australia; delivery times vary by location (most of our orders take the same time as the USA).

Age Restriction – 18+ Only

Our products are sold only to customers aged 18+. By ordering from Swords Kingdom, you confirm you are 18+ and legally allowed to purchase these products.

Custom-Made Orders - Delivery Time

For customised items (such as size or blade material, e.g., Damascus, carbon, J2, or 420 steel), the total delivery time is around 15–21 days.

Seasonal Deals & Discounts

Visit our Discount Offers page to see current seasonal deals, promotions, and special prices before you order.

Contact Our Support Team

Have questions about shipping or custom orders?

- WhatsApp: +1 917 383 3881

- Email: [email protected]

Or use our live chat for the fastest response from a real person (no bots).

Anonymous –

Great attention to detail — delivery was a bit of a wait.

Anonymous –

Blade came razor-sharp and ready to display. Packaging was perfect.